Rolling Grille Safe 4000 Type Keroll

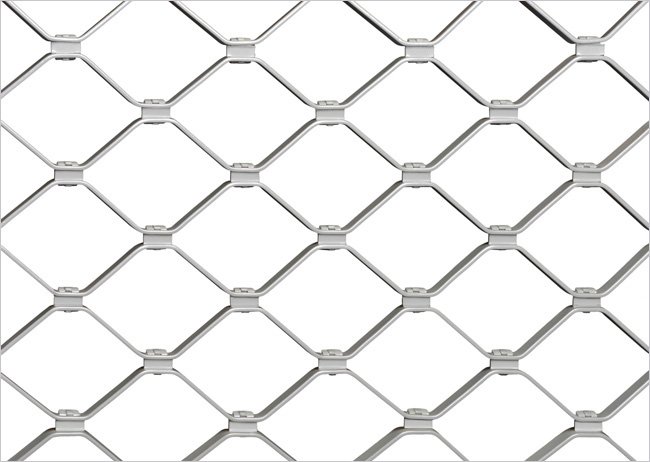

Safe 4000 Type Keroll Rolling Grille is a good security solution in a unique design made of galvanized flat steel or stainless steel. With its unique honeycomb pattern, Type Keroll is a stylish solution suitable for shops and premises that want an open Rolling Grille with good visibility in a high security class.

Medium F&P assurance level - Assurance level 30

Select security class

Standard

The mesh mat comes standard in galvanized flat steel, but is also available in stainless flat steel at an additional cost.

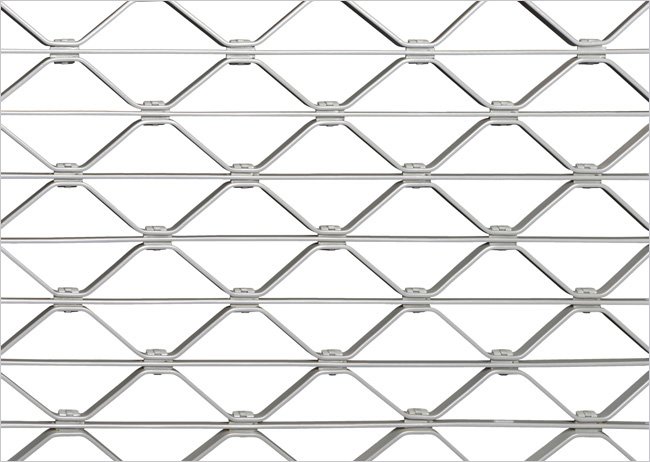

Reinforced version

Heavy-duty and reinforced construction tested to withstand hydraulic pressure/pull of 600 kg. Always made with a crossbar in the mesh opening.

Steel grilles with great visibility and airflow

Safe 4000 Type Keroll is an elegant and very open Rolling Grille that provides excellent visibility and airflow. The unique Honeycomb pattern creates a beautiful security solution for any store. Perforation rate: 78%.

Designed for a demanding security level

Type Keroll is a strong fuse that comes standard in galvanized or stainless flat steel at a higher price. Safe 4000 Type Keroll can be made according to the demanding standard EN1627 in RC3, however, this is only a test report and not a certificate like our Safe Pro products.

Strong and elegant protection for your business

The Paustian Koncept Store is an excellent example of how mechanical Mechanical security and Safe 4000 Type Keroll can be elegantly integrated and become a design element in store design.

Technical specifications

At Alux, we believe that a good collaboration leads to a good solution. We are always ready to advise you throughout your project or help you if you have any questions about our solutions.

Contact our service team at alux@alux.dk for non-binding advice and quotes.

-

The mesh mat comes standard in galvanized flat steel, but is also available in stainless flat steel at an additional cost.

-

Max width: 9000 mm

Dimension: 20x4 mm

Weight: 16 per m2

Mesh size: 185x120 mm

Max width: 7000 mm

Dimension: 18x4 mm

Weight: 15 per m2

Mesh size: 185x120 mm

Max width: 5000 mm

Dimension: 16x4 mm

Weight: 14 per m2

Mesh size: 185x120 mm

-

Heavy-duty and reinforced construction tested to withstand hydraulic pressure/pull of 600 kg.

Maximum grid dimensions

Dimension: 18x4 mm

Weight: 15 per m2

Max width: 4750 mm

Max height: 4750 mm

Mesh size: 185x120 mm

For EN1627-30 RC3, the mesh mat must always be made with a crossbar in the mesh opening.

-

Old standard in extruded aluminum profiles with noise reduction inserts and Teflon wear parts at the top.

Dimensions: F90 - 90 x 41 mm.

New standard in galvanized or stainless flat steel

Dimensions: U-profile 70 x 32 x 70 x4 mm.

-

Grille mats, guide rails and other parts are standard with a natural anodized or galvanized surface depending on the old and new standard.

All parts can be powder coated in any RAL color at an additional cost.

-

Steel with lacquered surface for internal mounting and galvanized surface for external mounting.

-

The grille is self-locking in the down position.

-

Standard is a built-in 230V tube motor.

Note: For large heavy grilles and special solutions, other types of motors or control options may be available.

-

Standard with key switch without impulse signal. With impulse signal, the product must always be equipped with a security package. Remote control, connection to ABA systems, CTS systems, etc. can be added at an extra cost.

-

- Cover box for roller pipes.

- Retractable guide rails. (not RC certified)

- Removable guide rails. (not RC certified)

- Manual locking.

- Roll-off protection.

- Safety package (Emergency stop, electrical terminal strip and photocell).

- Oops - emergency power supply.

-

See separate installation instructions.

-

- Functional testing of engine, steering and safety equipment.

- Check suspension, fasteners and slats for damage.

- Tightening of moving parts - Checking the self-locking effect

- Inspect guide rails and lubricate bearings if necessary.

Operation and maintenance should be performed min. once a year for products without automation. For products with automation (impulse signal), annual inspections are required by law and must be performed by a certified service company.

-

We recommend purchasing a tailored service agreement to ensure that operation and maintenance is carried out. This reduces the risk of downtime and extends the lifetime of the product.

Related products

Rolling Grille Safe 3000 Type Screen

Type Screen is a good and popular security screen in extruded aluminum profiles with an elegant harlequin design for a unique look and good visibility.

Roller Shutter Safe 3000

Safe 3000 is a strong security system with extruded aluminum profiles. The blind has fully enclosed profiles that close off viewing and airflow. Intended for a demanding security level where complete closure is required.

Fixed Grille Safe 3000 Type 100

Safe 3000 patented Fixed Grille in a unique design made of steel and aluminum that can be delivered in F&P protection class Blue or as EN 1627-30 RC3. Safe 3000's smart design has many applications.