The difference between

old Standard Thief Method and

new standard EN1627-30

EN1627-30 is the 'new' and applicable standard that sets far more stringent requirements for testing and certification of grilles and blinds than the old standard thief method.

Old standard: The standard thief method

The security product must be able to withstand pulling, pushing, prying and breaking through by 1-2 standard thieves using manual force and light tools.

Load requirements are what 2 standard thieves can perform.

New standard: EN1627-30

The security product must be able to withstand tension, compression, compression and penetration according to load requirements in accordance with EN1627-30.

Load requirements: RC2/300 kg, RC3/600 kg & RC4/1000 kg.

If the standard thief method is to be compared to EN1627-30, a standard thief must be as strong as a robot with hydraulics

EN1627-30 sets a new and elevated standard

for testing and certifying shell protection

As of January 1, 2014, Insurance & Pension (F&P) discontinued the "Standard Thief Method" test to move to a situation where all security products; i.e. doors, windows, roller shutters and grilles, must instead be tested and certified according to the pan-European standards EN1627 to EN1630.

The security classes in EN1627-30 are divided from Resistance class (RC) 1 to 6. For testing and certification of roller shutters and grilles, RC2 to RC4 are generally relevant, as RC5 and RC6 are intended for security tasks with extra high security requirements.

Overview of EN1627-30 protection classes

Resistance class 1 / RC1

Hydraulic drive, compression of 150-300 kg.

Swing pendulum: 50kg - drop height 450 mm.

Resistance class 2 / RC2

Hydraulic drive, 300 kg compression.

Swing pendulum: 50kg - drop height 450 mm.

Break-in time with light tools: 3 min.

Resistance class 3 / RC3

Hydraulic drive, 600 kg compression.

Swing pendulum: 50kg - drop height 750 mm.

Break-in time with standard tools: 5 min.

Resistance class 4 / RC4

Hydraulic drive, 1000 kg compression.

Break-in time with heavier tools: 10 min.

Resistance class 5 / RC5

Hydraulic drive, 1000 kg compression.

Break-in time with heavy-duty tools and power tools: 15 min.

Resistance class 6 / RC6

Hydraulic drive, pressurization of 1000 - 1500 kg.

Break-in time with extra heavy-duty tools and heavy-duty power tools: 20 min.

F&P security levels

Insurance companies have a number of requirements when insuring businesses. The insurance requirements result in a security level - and the security level is an expression of the risk the company has for a burglary. The level is determined by the goods the business has for sale and the value of these goods in stock, as well as the value of the IT equipment in use in the business. The more attractive your goods are to burglars, the more burglary protection is required.

There are six security levels in total, and each level details the requirements for locks, building reinforcements, grilles, electronic alarm monitoring, etc.

Security level 10 is the lowest level and security level 60 is the highest.

The difference between the old standard theft method

and the current standard EN1627-30

General differences in requirements

General requirements for

old standard theft method

- Roller shutters/roller grilles must be self-locking.

- No product width requirements for testing.

- No requirement for minimum engagement in guide rails.

- No quality assurance requirements.

General requirements by

EN1627-30

- Roller shutters/roller grilles must be self-locking.

- Must be supplied max. 100 mm wider than tested product.

- Must be delivered max 50% higher than tested product.

- Test method after surface or niche mounting

with freely accessible guide rails.

- Requirement for installation instructions and labeling of

product upon certification.

- Require annual audits to maintain certification.

- Documentation and quality assurance system requirements

for certification.

Requirement difference when testing

Old standard - The Standard Thief Method

New and applicable standard - EN1627-30

Requirement difference when testing

Old standard - The Standard Thief Method

In general, the installation/attachment of grilles/blinds should be as durable as the product itself, so there are no weak links in the entire solution.

Requirements for the installation base

The installation base is assessed - is it concrete, masonry, aerated concrete, plaster, wood, etc. If the foundation is not sufficient for the security product to be broken down by 2 standard thieves with light tools and manual force, the building component must be reinforced or another installation option must be chosen.

Requirements for fastening materials

The choice and number of fasteners is assessed based on the above requirements. Please refer to the supplier's tables for fastener values.

Requirements for self-locking effect

After every installation, the self-locking function must be checked by performing a lifting test.

Installers perform the lifting test on the fuse product by lifting the fuse so that there is a maximum opening of 120 mm.

New and applicable standard - EN1627-30

In general, the installation/attachment of grilles/blinds should be as durable as the product itself, so there are no weak links in the entire solution.

Requirements for the installation base

The installation base is assessed - Is it concrete, masonry, aerated concrete, plaster, wood, etc. If the foundation is not sufficient for the protection product to be broken down by tension, pressure and compression at RC2/300 kg, RC3/600 kg or RC4/1000 kg respectively, the building component must be reinforced or another installation option must be selected.

Fastener requirements

The choice and number of fasteners is calculated based on the above requirements. Please refer to the supplier's tables for fastener values.

Requirements for self-locking effect

After every installation, the self-locking function must be checked by performing a lifting test.

Installers perform the lifting test on the safety product by lifting the fuse so that there is a maximum opening of 150 mm. The mounted product must also be able to withstand 300 kg for RC2, 600 kg for RC3 products and 1000 kg for RC4.

The lifting test is a check that the product is adjusted correctly and that the product cannot be pressed up immediately. It is the manufacturer's responsibility that the product is designed in such a way that the product can comply with the requirements of the product's classification.

Stronger security and

less risk with EN1627-30

Evaluation

Product width requirements ensure that security products comply with security requirements

The consequence of not requiring product width is that narrow grilles/blinds (with low elasticity and high stiffness) are tested under the standard theft method, but very wide grilles/blinds (with high elasticity and deflection) can be delivered under the same security class.

For new standards, the product must be delivered max. 100 mm wider than the tested product.

EN1627-30 places far greater demands on the mounting and fastening of the security product

In the 'new' and applicable standard EN1627-30, the load requirement is tension, compression and jacking at RC2/300 kg, RC3/600 kg or RC4/1000 kg respectively, which is far greater than what 2 standard thieves can perform under the standard thief method.

EN1627-30 certified products for better security and minimized risk

With EN1627-30, a significantly higher standard of certified security products is achieved, providing customers and insurance companies alike with a better security solution and minimizing the risk of successful break-in attempts resulting in inconvenience and compensation.

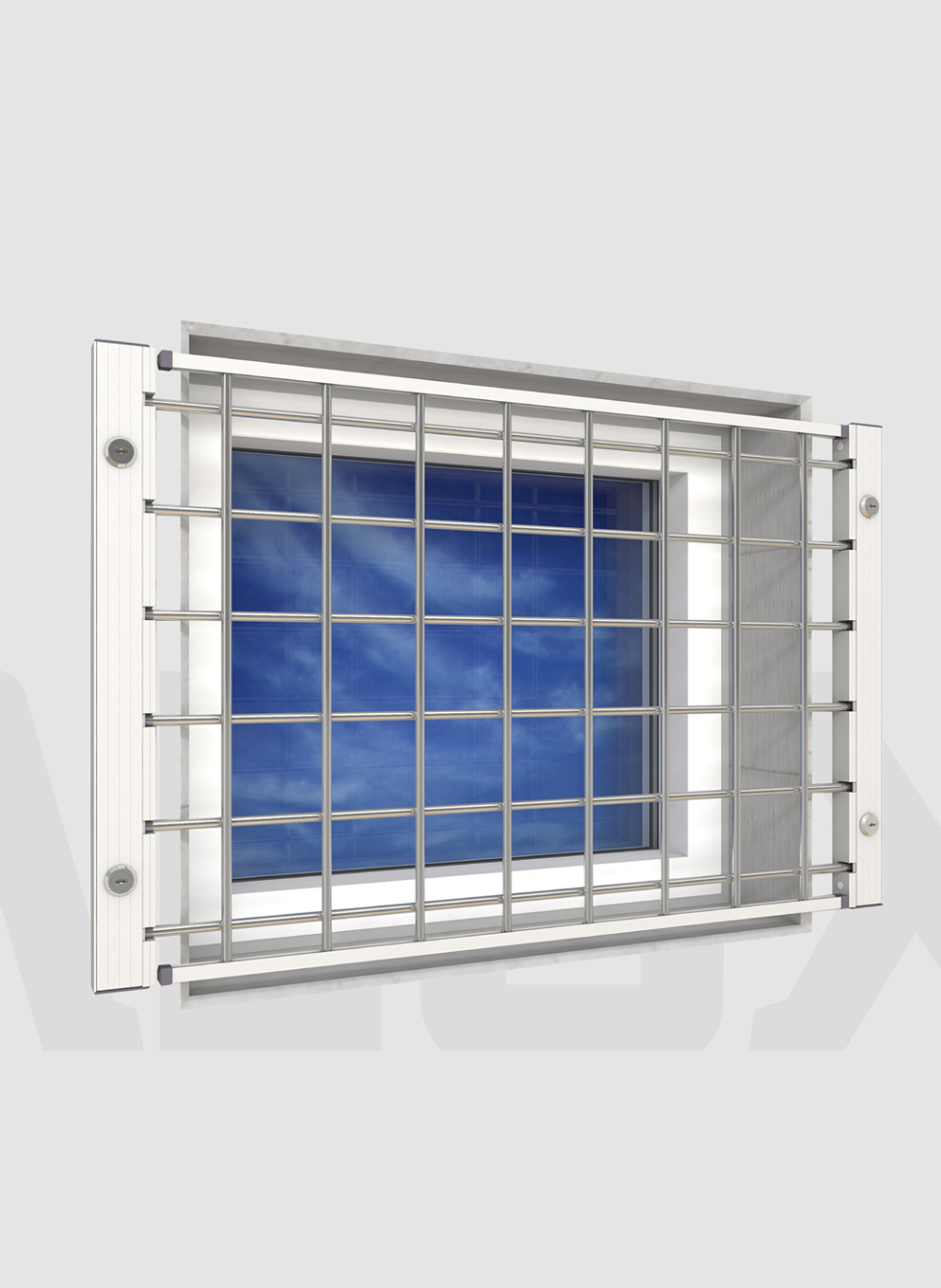

Our EN 1627-30 certified mechanical burglary protection products